Precast Concrete 101: The Foundation of Modern Construction

Welcome to the Willis Construction blog, where we delve into the intricacies of precast concrete and its pivotal role in modern construction. As industry leaders in the Western United States, we aim to provide architects, builders, general contractors, and engineers with comprehensive insights into the technology, benefits, and applications of precast solutions.

What is Precast Concrete?

Defining Precast Concrete and Its Core Components

Precast concrete is a construction product produced by casting concrete in a reusable mold or “form” which is then cured in a controlled environment, transported to the construction site, and lifted into place. This process contrasts with standard concrete which is poured and cured on-site.

Manufacturing Process and Precision

The process begins with creating a precisely leveled casting surface. The mold is prepared, and concrete is poured, often with embedded reinforcements such as steel bars. Once cured, the panels are stripped from their molds, finished to specification, and inspected for quality. The precision in manufacturing ensures each panel meets the stringent standards of durability and performance.

Types of Precast Concrete by Willis Construction

- Architectural Precast: Durable, moisture-resistant, and aesthetically versatile. Custom colors and textures are available, including natural stone veneers and thin brick applications.

- Glass Fiber Reinforced Concrete (GFRC): A lightweight, flexible option ideal for high-rise buildings and complex shapes. GFRC panels are reinforced with alkali-resistant glass fibers, making them robust yet easy to handle.

- Thinshell Precast: Combines the aesthetic appeal of traditional precast with a lighter weight, making it easier to install without compromising on durability.

- Structural Precast: Includes elements like planks, vertical walls, and unique custom components for various structural applications.

The Technology Behind Precast Concrete

Advanced Manufacturing Technology

Willis Construction employs cutting-edge technology in its manufacturing plants. This includes 3D modeling and computerized-numerical control (CNC) machines that ensure precise, intricate designs are achieved consistently.

3D Modeling and CNC Precision

3D modeling software allows for detailed planning and visualization of each project. CNC machines then use these models to carve molds with exceptional accuracy, ensuring each precast panel fits perfectly into its intended place.

Significance of PCI Certification

Willis Construction’s plants are PCI Certified, reflecting a commitment to quality and sustainability. This certification ensures that every piece of precast concrete meets high standards of performance, reliability, and environmental responsibility.

Benefits of Precast Concrete Solutions

Durability and Longevity

Precast concrete is known for its robustness, resistance to environmental factors, and low maintenance requirements. It ensures the longevity of structures, making it a cost-effective choice in the long run.

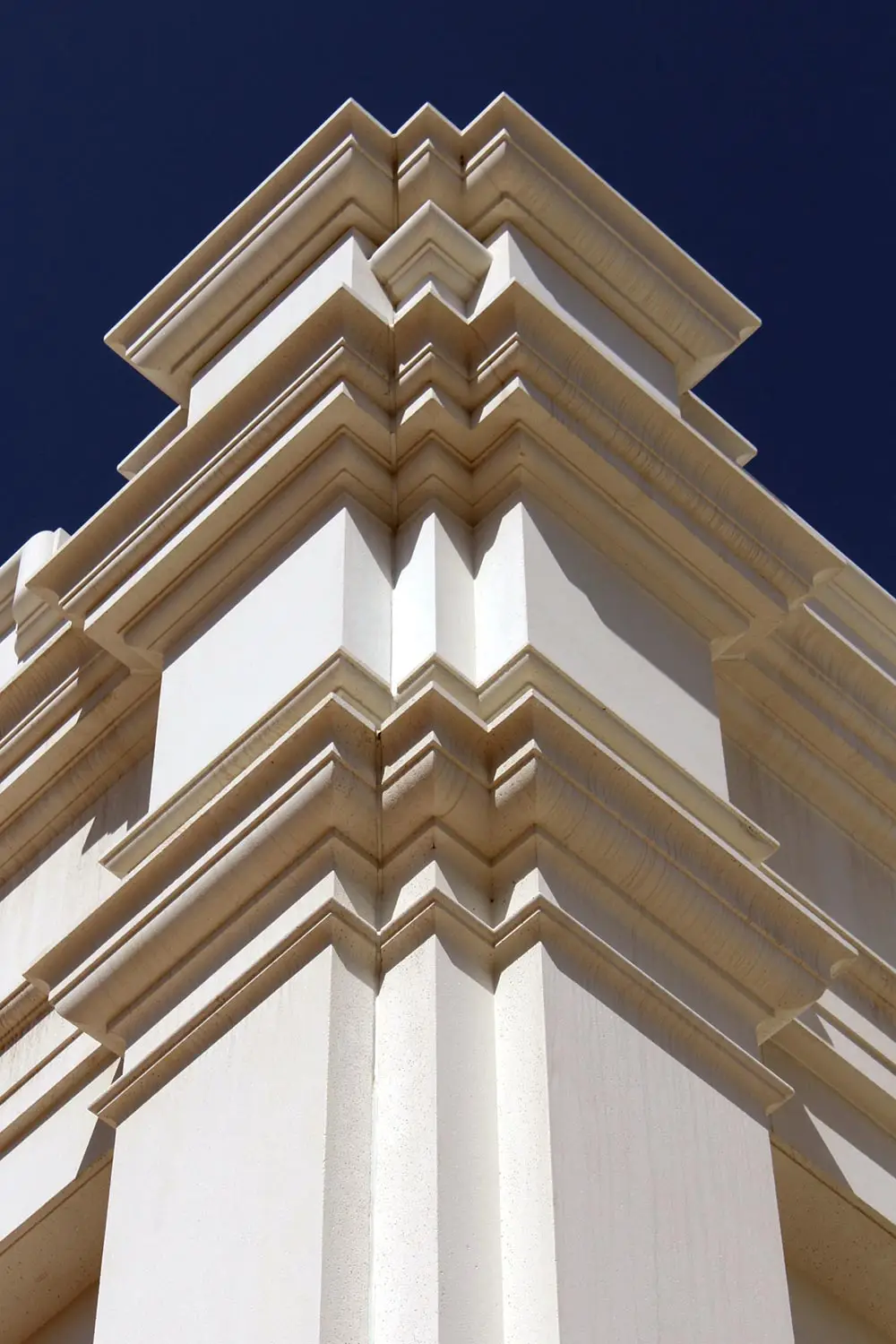

Aesthetic Versatility

With a wide range of design options, precast concrete can be customized with various colors, textures, and form liners to simulate materials like wood, brick, and stone. This versatility allows for creative and unique architectural expressions.

Cost-Effectiveness

Precast solutions offer significant cost savings through reduced on-site labor, faster installation times, and minimized material waste. The efficiency in production and installation translates to overall project savings.

Environmental Sustainability

Precast concrete supports sustainable building practices. Its production involves energy-efficient processes, and the materials used can contribute to a reduced carbon footprint. Additionally, its high insulative value aids in energy conservation in buildings.

Willis Construction’s Expertise in Precast Solutions

45 Years of Experience

With over four decades in the precast industry, Willis Construction has built a reputation for innovation and excellence. Our team’s dedication to quality craftsmanship is evident in every project we undertake.

Notable Projects and Solutions

From commercial offices to state-of-the-art hospitals, Willis Construction has implemented unique precast solutions that meet diverse architectural needs. Noteworthy projects include the Broad Museum in Los Angeles and the UCSF Medical Center at Mission Bay.

Collaboration with Industry Professionals

Our success is built on strong partnerships with architects, builders, and engineers. By working closely with these professionals, we ensure that every project achieves its goals in design, functionality, and efficiency.

Applications of Precast Concrete in Modern Construction

Diverse Applications

Precast concrete is used in various construction projects, including:

- Commercial Office Buildings and Retail Spaces: Durable and aesthetically pleasing panels for high-traffic areas.

- Residential Housing: Efficient solutions for housing developments, including multi-family units and high-rise apartments.

- Healthcare Facilities: Durable and hygienic panels for hospitals and medical centers.

- Educational Institutions: Cost-effective and sustainable options for schools and universities.

- Sports Stadiums and Recreational Facilities: Robust solutions that withstand heavy use.

- Specialty Projects: Custom applications for unique architectural requirements.

Case Studies of Success

Our portfolio includes projects like the Centerra Apartments in San Jose, where a combination of architectural precast and GFRC was used to create a stunning facade. Each project showcases our ability to meet complex design and structural needs efficiently.

Conclusion: Partnering with Willis Construction for Your Precast Needs

Choosing Willis Construction as your precast partner brings numerous benefits. Our expertise, commitment to quality, and innovative solutions make us the ideal choice for your next construction project. Reach out to us for consultations, design assistance, and to explore the many possibilities of precast concrete.