GFRC 101: Exploring Glass Fiber Reinforced Concrete

Introduction

What is GFRC?

Definition and Core Components

Glass Fiber Reinforced Concrete, commonly known as GFRC, is a specialized form of concrete that uses glass fibers to enhance its structural properties. Unlike traditional concrete, GFRC comprises a cementitious skin reinforced with alkali-resistant glass fibers, resulting in a highly durable and flexible material. This composite panel is typically 3/4″ thick and attached to a metal stud frame system.

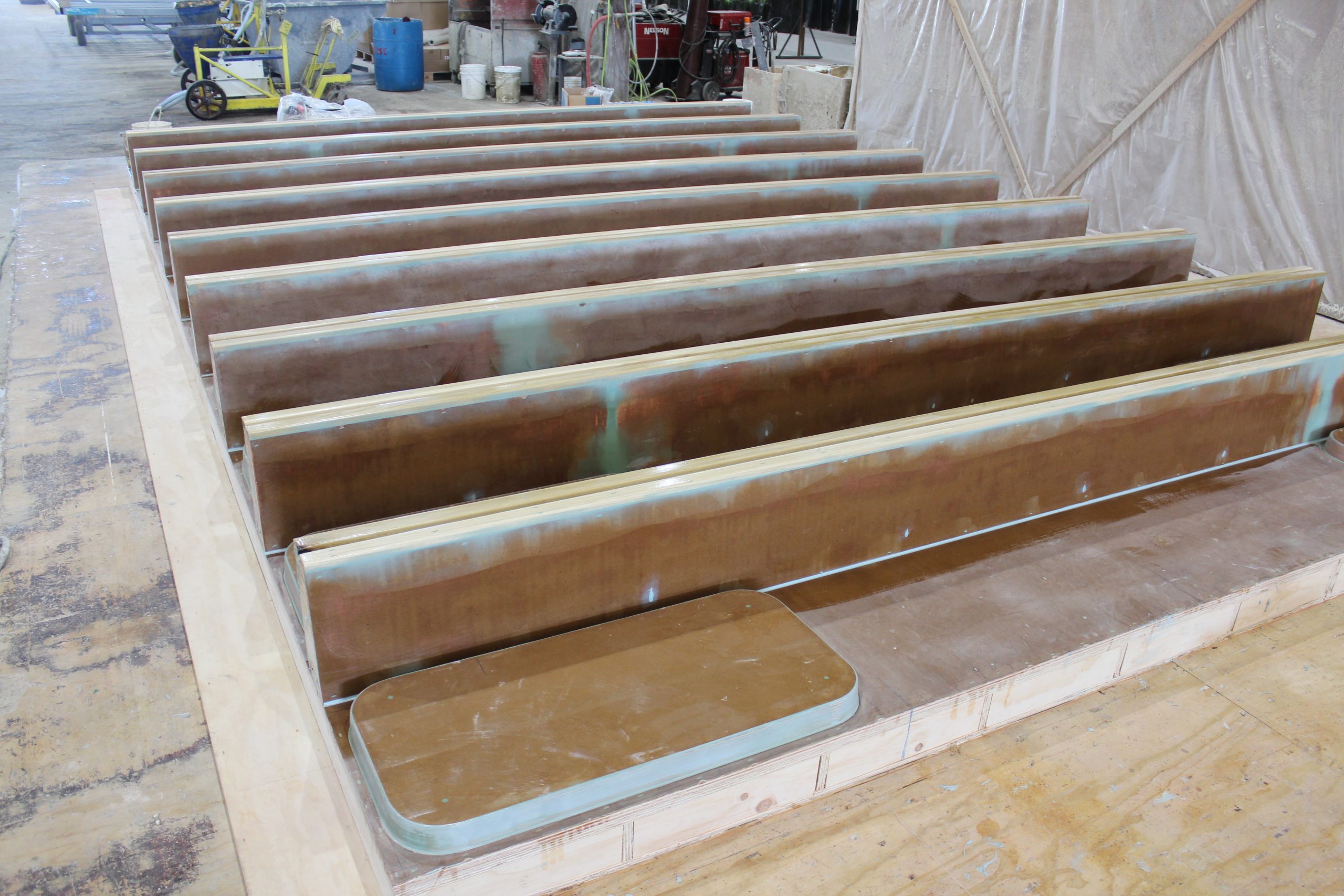

Manufacturing Process

The manufacturing of GFRC panels involves a meticulous process to ensure precision and quality. The process begins with the custom face mix sprayed into a mold, followed by multiple passes of glass fiber reinforced concrete to achieve the desired thickness. The structural frame, usually made of structural tube members, is integrated with the GFRC using L or T-shaped galvanized pins. Once cured, the panels are stripped from the mold and sandblasted to the architect’s specifications.

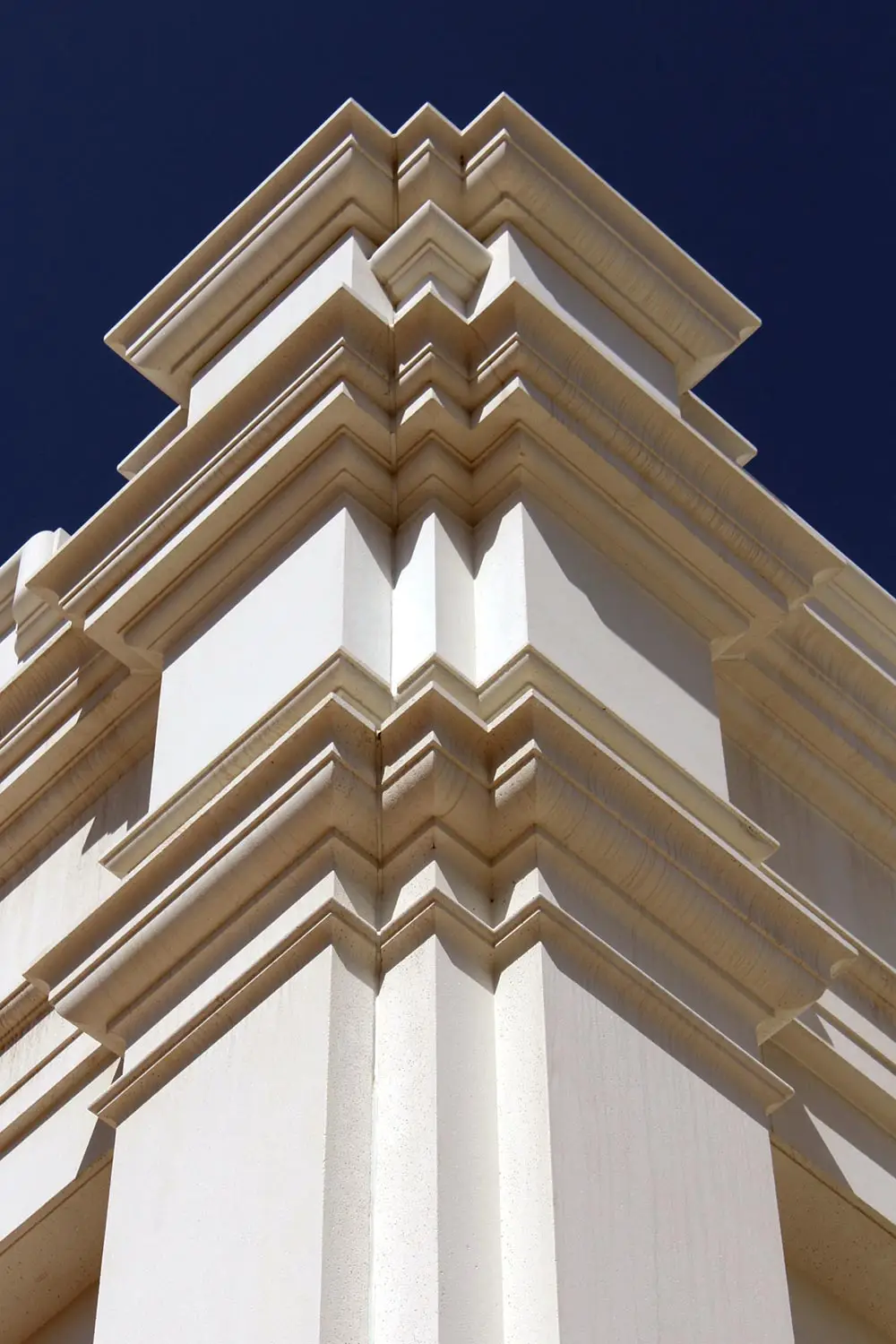

Specializations at Willis Construction

At Willis Construction, we specialize in creating GFRC panels that cater to diverse architectural needs. Our expertise includes producing panels with intricate shapes, multiple colors, and finishes, including light and heavy sandblast textures. We also offer custom form liners to emulate materials such as wood, limestone, and brick, providing limitless design possibilities.

The Technology Behind GFRC

Our state-of-the-art manufacturing facilities leverage advanced technology and equipment to produce GFRC panels. Utilizing 3D modeling and computerized numerical control (CNC) machines, we achieve unparalleled precision in creating complex and detailed designs. Our commitment to quality is reinforced by our PCI certification, ensuring adherence to the highest industry standards for performance and sustainability.

Benefits of GFRC Solutions

Durability and Longevity

GFRC is renowned for its exceptional durability and longevity. Its composition makes it resistant to environmental factors, reducing the need for frequent maintenance and repairs. This resilience ensures that structures built with GFRC maintain their aesthetic and functional integrity for years to come.

Aesthetic Versatility

One of GFRC’s standout features is its aesthetic versatility. Architects can choose from a wide range of colors, textures, and finishes to match their design vision. The ability to create intricate shapes and emulate other materials adds to its appeal, making GFRC a preferred choice for innovative architectural projects.

Cost-Effectiveness

GFRC offers significant cost savings through reduced material and labor costs. Its lightweight nature means less structural support is needed, leading to savings in steel and foundation costs. Additionally, the prefabricated panels speed up the installation process, minimizing on-site labor and reducing project timelines.

Environmental Sustainability

Incorporating GFRC into construction projects supports sustainable building practices. The material’s high strength-to-weight ratio reduces the overall carbon footprint, and its durability extends the lifespan of structures, decreasing the need for resource-intensive repairs and replacements.

Willis Construction’s Expertise in GFRC Solutions

With over 45 years of experience, Willis Construction has established itself as a leader in the precast industry. Our portfolio showcases numerous successful projects where GFRC played a pivotal role in achieving architectural excellence. From high-rise buildings to intricate facades, our collaboration with architects, builders, and engineers ensures the seamless integration of GFRC into diverse construction projects.

Applications of GFRC in Modern Construction

GFRC’s versatility makes it suitable for a wide range of applications. It is ideal for commercial office buildings, residential housing, healthcare facilities, educational institutions, and specialty projects. Our case studies highlight the transformative impact of GFRC in projects such as the Broad Museum in Los Angeles, where the material’s flexibility and aesthetic appeal were fully realized.