Citrus Tower Corporate Plaza

image #2

image #3

image #4

image #5

image #6

image #7

image #8

image #9

image #10

image #2

image #3

image #4

image #5

image #6

image #7

image #8

image #9

image #10

|

Location:

Riverside, CA

Owner:

Regional Properties Inc.

Architect:

Nadel Architects

Engineer:

(Below- Grade Parking): Seneca Structural Engineering, (Above-Grade Building): BP Consulting Engineers

Contractor:

McCormick Construction Co.

Project Highlights:

-Design Build project

-Multiple mix design colors in the same panel

-Granite veneer on GFRC Ground Floor panelsd

Precast Products:

GFRC spandrels, crowns, arches, and granite clad column covers

|

Precast Aesthetics / Winter 2013 Ascent / Craig A. Shutt / Slug: AESTHETICS OVERVIEW

Precast Concrete Offers Aesthetic Versatility

Designers turn to precast concrete to meet owners’ demands for signature designs or to blend in with a community, and precasters respond

By Craig A. Shutt

Aesthetic requirements for buildings are expanding, as owners battle to attract tenants and create a distinctive appearance. That can mean making a signature statement with a contemporary, dramatic look or blending seamlessly into a neighborhood or campus environment. A desire for more detailing also has grown, as designers look to add visual interest and depth to facades.

In many cases, designers are turning to precast concrete to meet these needs for a variety of reasons. Its plasticity allows it to provide depth and geometric shapes that create an arresting style. It also can replicate the look of brick, stone, and masonry in faster, more economical and more sustainable ways than the real materials can. Precaster’s capabilities in creating unique shapes in innovative forms and providing multiple colors in one component provides faster fabrication and erection, eliminating trades and cutting time from the schedule. All of these attributes blend to produce economical, quickly constructed and aesthetically pleasing designs.

The following project gives an idea of some of the techniques being used throughout North America by precasters to meet the growing needs of owners, designers, and building users.

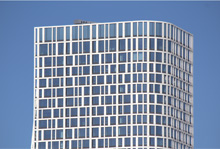

Citrus Tower

A variety of complications arose for the design of Citrus Tower Corporate Plaza in Riverside, Calif. The large office building stands on a high-profile corner location near a major highway. As a result, the owner’s goal for the aesthetic design was to “create a memorable architectural statement that was a friendly neighbor to the community, with ‘traditional’ quality architecture to which no one would be indifferent,” says Herb Nadel, principal at Nadel Architects.

The architectural design expressed a rich and grand visual for the entire building, which was clad with glass-fiber reinforced concrete (GFRC) panels, some of which were embedded with granite veneers. Each bay opening features a two-colored arched spandrel with multifaceted granite-clad GFRC column covers at each structure column.

GFRC consists of Portland cement, fine aggregates, acrylic co-polymers and glass fibers that reinforce the concrete similar to the steel reinforcement in concrete. The small fibers provide great flexibility and versatility in creating components, allowing the mixture to be sprayed onto forms to create unusual shapes. The light weight and consistency of the glass fibers reduce the weight of the components, making them considerably lighter than traditional precast concrete components with much the same durability and appearance.

Along its base, the building features tall arched windows and a larger arched entry, which extends up to interrupt the line of large, square windows one story up. Above this are tall, vertical expanses of glass surrounded by precast concrete columns in two tones, a rose hue and a buff color, that lead to a setback penthouse level that serves as a roof crown, which also was clad in GFRC.

GFRC was chosen for the project due to its capabilities in achieving the multi-hued look that was desired and its light weight. The building’s foundations are set above a four-story subterranean parking structure on a post-tensioned slab, which required the above-ground structure to be as light as possible. But the designers also wanted to use precast concrete materials to maximize longevity and durability.

Several other options were considered, including stone, 4-inch-thick precast concrete panels, and exterior cement plaster. All were intended to provide a stone-like appearance to meet the owner’s requirements, Nadel explains. Evaluations showed that GFRC would meet all of the needs, providing a similar appearance to what precast concrete could provide while eliminating some of the necessary weight. The GFRC’s light weight also allowed a reduction in some of the structural steel framing being used, saving costs.

The ability for the GFRC components to cast multiple colors in one panel also provided budget savings. Using the various colors required close pre-planning with the precaster to ensure clear transitions between colors. The first mix design was sprayed with the form being masked. The masking is then removed, and the mix is allowed to stiffen but not completely set up. That allows the first pour to be secure when the second mix-design color is sprayed in.

In all, three mix designed were created, with some panels including all three. Two finishes, light and heavy sandblasting, also provided textural variety. The granite attachment to the panel is achieved by spraying a thickened GFRC back-up skin to the back side of each granite piece. Additional GFRC is consolidated to cover metal clips that attach to the granite. Willis Construction Inc. created the GFRC components.

The building’s most dramatic feature is the rounded tower on the corner, which extends past the roofline. Its canopy consists of compound-radius GFRC panels, with granite cladding the topmost band.

The design reflects a similar project that was to be designed by Nadel in Riverside. “We showed this idea to the client, and we thought the city might be receptive to this idiom of architecture because it blended so well with other structures throughout the city,” Nadel says. “The curved corner becomes a beacon and a very identifiable form, giving the building distinctive characteristics along with natural colors that reflect the general built environment.”

The designers worked closely with the precaster to find the proper mix of colors and textures. Full-size mockups of the panels were created to confirm the choices. “Those crystallized our selections, and the process of creating them was very successful,” he says.

Working with the GFRC panels was seamless, he notes. “Its flexibility created forms and shapes as needed and worked well with the window system. The needed shapes were easily achieved. Detailing the panels also was a simple process, since the material can be configured in virtually any shape or form because of its plasticity.”

The design process for the dome required complex calculations, he adds, due to the costs, weight, and the limited resources available to build such a complicated structure. “The cost factor played a major role in how it was ultimately constructed,” he says. “There are virtually no straight pieces, since the entire dome and all of its supports are curvilinear.”

Cranes were set into one lane of traffic to allow erection, and the process moved smoothly. “Delivering and erecting the GFRC components was a straight-forward and simple process,” he says. “There were no complications.”

The GFRC offered a great option for this project, he says. “As far as I’m concerned, working with GFRC, or precast concrete, is a fairly simple design process. We have used it innumerable times. I would highly recommend the use of this material because of the design excellence that can be achieved at a very economical price.”

The community agrees that the project fits well into the neighborhood and provides a dramatic, signature style. “We have been repeatedly told that the building is a beautiful addition to the city,” he says. “It is compatible, memorable, and has an excellent standard of quality. It has raised the bar for architectural excellence within this community.”

Willis Construction has been providing Architectural Precast Concrete building panels and products for the construction industry since 1979. Willis Construction is dedicated to providing Owners, Architects, and General Contractors with the design and engineering expertise necessary to meet the building challenges of today and the future. The quality, durability, and long life of Architectural Precast Concrete, Thinshell, and GFRC (Glass Fiber Reinforced Concrete) systems provide a wide range of design options for virtually every type of building. Contact us to decide which system would be best suited for your next project.