Modern construction demands materials that balance strength, design flexibility, and efficiency. Glass Fiber Reinforced Concrete (GFRC), introduced in the U.S. in the 1970s, has proven to be a durable, lightweight material that continues to meet the evolving needs of architects, developers, and general contractors. GFRC remains a staple for innovative design and functional excellence.

What is Glass Fiber Reinforced Concrete (GFRC)?

Glass Fiber Reinforced Concrete (GFRC) is a composite material made from fine aggregates, concrete, and reinforced with alkali-resistant (AR) glass fibers. The panel has a steel frame with GFRC skin. This composition makes GFRC panels lightweight, durable, and versatile, especially for architectural precast applications.

Components of GFRC Panels:

- Cement: High-quality Portland cement.

- Sand: Fine aggregates for smooth finishes.

- Glass Fibers: AR glass fibers enhance tensile strength.

- Polymer Additives: Improve flexibility and crack resistance.

- Steel Frame: Provides structural support for GFRC panels.

Key Benefits of GFRC Panels in Construction

- Lightweight Durability

GFRC panels are significantly lighter than traditional concrete, reducing structural loads and simplifying installation. Their strength ensures resilience to weather and environmental factors, making them ideal for high-rise buildings, facades, and decorative elements.

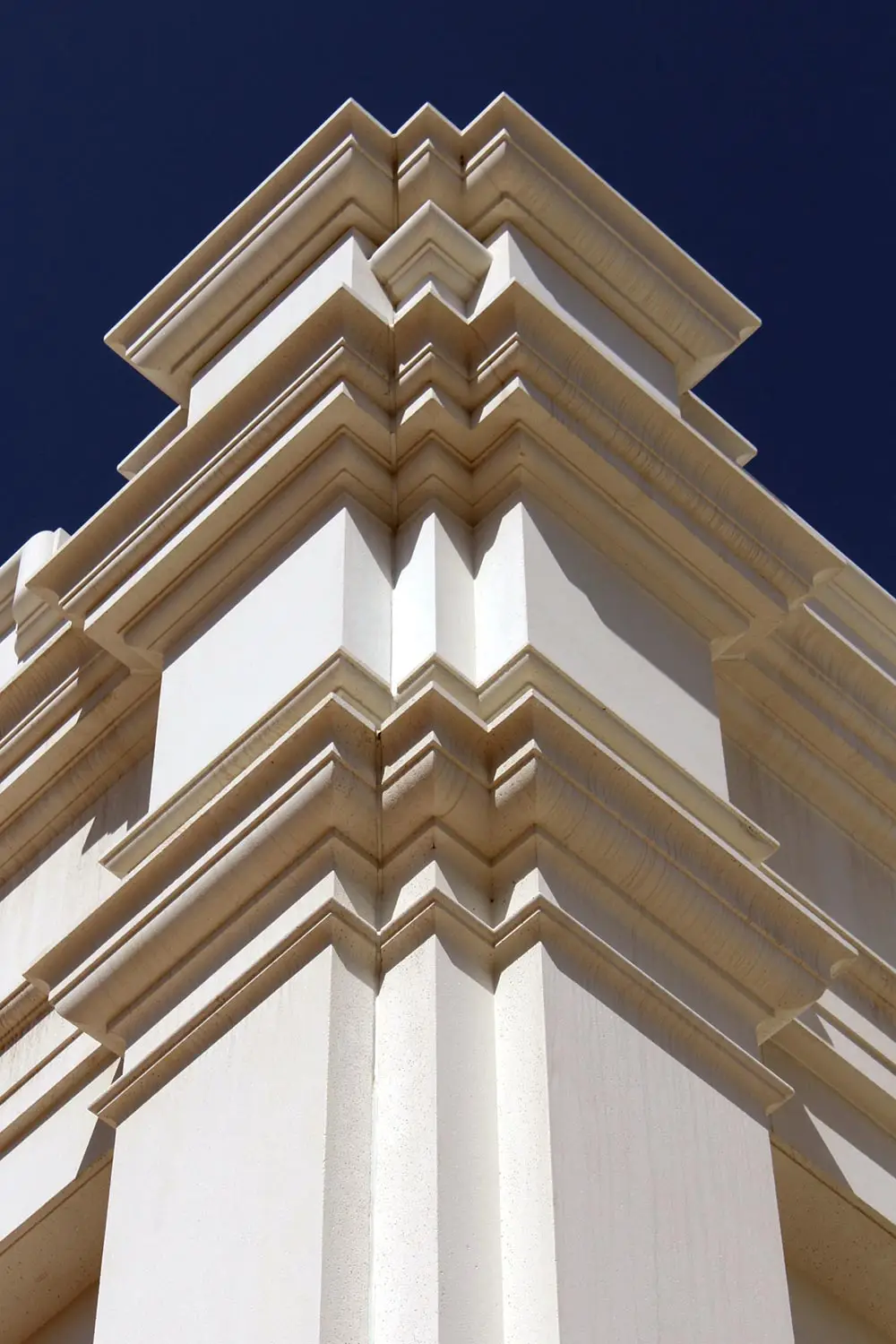

- Design Flexibility

GFRC panels enable intricate designs, custom finishes, and unique shapes. Architects can achieve a high level of detail while maintaining structural integrity, aesthetics, and functional requirements.

- Longevity and Low Maintenance

GFRC panels offer long-term durability with resistance to cracking, corrosion, and environmental wear. Their low-maintenance nature makes them a cost-effective choice for developers focused on lifecycle efficiency.

- Sustainability

The precast concrete industry has performed studies on the environmental performance of its products that are incorporated into a building. The manufacturing impact was compared to the overall environmental impact of the building’s life, i.e. “life-cycle assessment”. According to the Precast/Prestressed Concrete Institutes Comparative Life-Cycle Assessment of Precast Concrete Commercial Buildings Overview/Executive Summary, the precast manufacturing through the building construction phase accounts for less than 4% of the total environmental impact vs the building’s operational stage contributing to more than 96% of the total impact.

- Efficient Installation

Precast GFRC panels are manufactured off-site and arrive ready to install, reducing on-site labor and minimizing delays. This streamlined process supports tighter project timelines.

Featured GFRC Project: The Broad Museum

The Broad Museum in Los Angeles, CA, showcases the creative potential of GFRC. Its unique façade, known as “The Veil,” uses GFRC panels to create a honeycomb-like structure that balances artistic vision with functional design.

Key Project Details:

- Material Used: GFRC panels.

- Design Challenge: Achieve intricate geometry while maintaining structural integrity.

- Outcome: Over 2,500 custom GFRC panels manufactured by Willis Construction, resulting in a seamless integration of design and durability.

This award-winning project demonstrates GFRC’s ability to meet complex architectural goals while supporting efficient construction practices.

Applications of GFRC Panels in Construction

GFRC panels are widely used across various sectors, including:

- Architectural Facades: Lightweight, customizable panels for unique designs.

- Commercial Buildings: Durable and aesthetically versatile precast solutions.

- Public Infrastructure: Panels tailored for government buildings and educational facilities.

- Decorative Features: Columns, cladding, and artistic accents.

The Timeless Appeal of GFRC

While GFRC has been in use for decades, its adaptability and enduring benefits make it a go-to material for modern architectural design. Developers appreciate its cost-efficiency over time, architects value its design flexibility, and contractors rely on its lightweight strength for seamless installations.

At Willis Construction, we’re proud to leverage GFRC’s capabilities to deliver innovative and high-quality solutions that meet the demands of today’s construction landscape.

Contact us today to learn more about how GFRC panels’ can elevate your next project with superior design and performance.